Nandar

NATURAL DYE & HAND-WEAVING

Name: Nandar Soe Aye

Age: 40 years

From: Amarapura

Job: Owner/ Founder Hnin Witthmone Natural Dye Cotton Centre

Handweaving and natural dyeing

Started in 2001

My interest in the handweaving technique and natural dyes started at a young age. My mother was a principal at the Saunders institute in Amarapura (weaving and vocational institute).

I prefer to work with natural dyes because it is rare compared to chemical dyeing. The technique fascinates me, and the possibilities are endless. It is impressive to see what colours you can create using natural sources and off course it is less harmful compared to working with chemical dyes.

I also work more towards the use of natural fibres such as bamboo and banana. I am aware of the advantages of the material and for the environment. I believe in the quality of natural fibres and the benefits they have when wearing it. For example, bamboo fibre is great against heat in the warm season and on the other hand, keeps us warm in the cold season. Banana fibre offers excellent protection against bacteria’s.

My workshop started with two people and a loom, and now I work with 23 weavers in my workshop. Some of them are graduates/ students trained at the Saunders Weaving Institute. Others are girls from around Myanmar, who also attend University here and look for jobs. Everyone can weave when they get employed, but they learn to make other types of products/designs and use other fibres. Besides the younger students, there are 14 women. The women live around Amarapura and have been working for a long time in the workshop.

The patterns and designs they work on are dependent on their skills and work experience. Besides the fixed orders we make some personal designs. Together with the women in my workshop, we come up with new ideas and designs that could work on different fabrics.

My future perspective is to educate more people in the technique of natural dyeing and create more awareness around it. Also, I would like to expand my business and employ more women in my workshop.

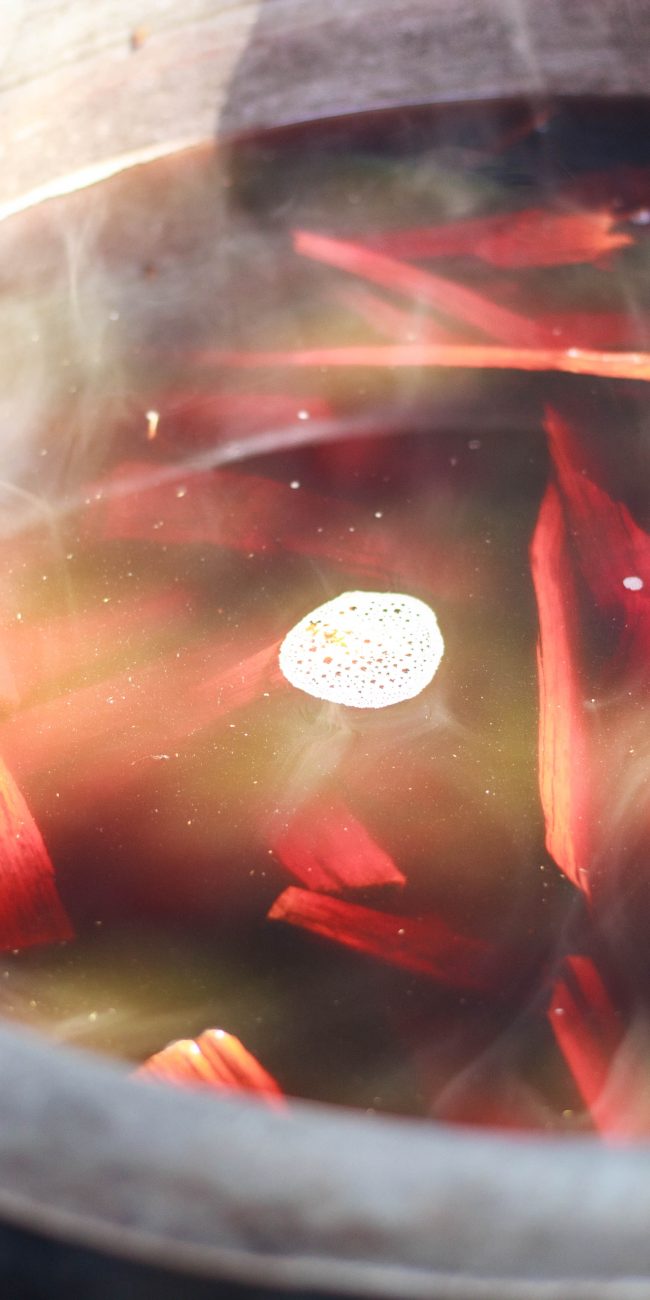

Natural dyes are an efficient and creative way to reduce environmental impact and enable the use of non-toxic, low impact solutions. The yarns are boiled in dyes made out of flowers, plants or barks in combination with alum and salt. Alum is a chemical, but it is measured to ensure that it is not damaging for the environment, as the alum soaks into the yarn and doesn’t go in the wastewater. After the boiling, the yarns get dipped in and line dried. This process is repeated multiple times, to deepen the colour.

he process of handweaving designs takes years of experience. The looms at the workshop are made out of wood and bamboo and besides keeping focus, it is also physical work. For the handweaving, both handspun and machine-spun yarn and thread are used. After the spinning process, the designs for the fabric are set up on the handloom. This takes great precision and knowledge. It is a time-consuming task, which can take up to five days, with no room for errors. The handweavers use handspun cotton for the weft and machine-spun cotton for the warp to make the fabrics. These get attached by passing the weft yarn through the warp threads with a boat-shaped shuttle.